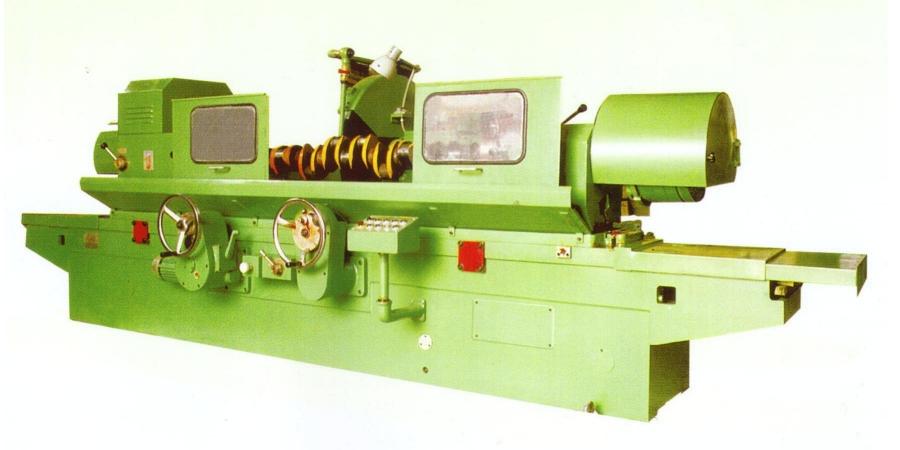

| Crankshaft Grinding Machine |

|

|

| Item |

MQ8260A /1600 |

MQ8260A/1800 |

MQ8260A/2000 |

MQ8260C |

| Max. work swing diameter × Max. work length: |

ф580×1600mm |

ф580×1800mm |

ф580×2000mm |

ф600×1600mm |

| Work diameter ground with steady rest: |

ф30-ф100mm |

ф30-ф100mm |

ф50-ф120mm |

ф30-ф100mm |

| Throw of crankshaft: |

110mm |

110mm |

120mm |

110mm |

| Max. work length: |

1400mm( in 3 jaw chuck ) / |

1600mm( in 3 jaw chuck ) / |

1800mm |

1400mm |

| 1600mm ( between centers ) |

1800mm ( between centers ) |

2000mm |

1600mm |

| Max. work weight: |

120kg |

120kg |

150kg |

120kg |

| Headstock |

|

|

|

|

| Center height: |

300mm |

300mm |

300mm |

300mm |

| Work speed ( 3 steps ): |

25/45/95 r/min |

25/45/95 r/min |

30/45/65/100 r/min |

25/45/85 r/min |

| Wheel head: |

|

|

|

|

| Max. cross movement: |

185mm |

185mm |

185mm |

185mm |

| Wheel head rapid approach and withdrawal: |

100mm |

100mm |

100mm |

100mm |

| Wheel feed per turn of cross feed hand wheel: |

1mm |

1mm |

1mm |

1mm |

| Per grad. Of cross feed hand wheel: |

0.005mm |

0.005mm |

0.005mm |

0.005mm |

| Grinding wheel |

|

|

|

|

| Spindle speed ( 2 steps ): |

740 / 890 r/min |

740 / 890 r/min |

740/ 890 r/min |

740/ 890 r/min |

| Peripheral speed: |

25.6-35 m/sec |

25.6-35 m/sec |

25.6-35 m/sec |

25.6-35 m/sec |

| Wheel size: ( O.D. ×With × Bore ) |

ф900 × 32 × ф305mm |

ф900 × 32 × ф305mm |

ф900 × 32 × ф305mm |

ф900 × 32 × ф305mm |

| Tble |

|

|

|

|

| Table traverse per turn of hand wheel: |

5.88mm (coarse) / 1.68mm (fine) |

5.88mm (coarse) / 1.68mm (fine) |

5.88mm (coarse) / 1.68mm (fine) |

5.88mm (coarse) / 1.68mm (fine) |

| Table swivel ( taper 18/100 ): |

5° |

5° |

5° |

|

| Table swivel per grad of scale ( taper 1:50 ): |

10′ |

10′ |

10′ |

|

| Overall capacity of motor: |

9.82kw |

9.82kw |

11.12kw |

9.82kw |

| Overall dimension (L × W × H): |

4166 × 2037 × 1584mm |

4166 × 2037 × 1584mm |

4900*2037*1584 |

4166 × 2037× 1584mm |

| Weight: |

6000kg |

6200kg |

7000kg |

6000kg |

| Working accuracy: |

|

|

|

|

| ovality |

0.005 |

0.005 |

0.005 |

0.005 |

| cylindricity |

0.01 |

0.01 |

0.01 |

0.01 |

| roughness Ra |

0.32 |

0.32 |

0.32 |

0.32 |

| Main accessories: |

|

|

|

|

| Jaw chuck |

2 sets |

2 sets |

2 sets |

2 set |

| Wheel dresser |

1 set |

1 set |

1 set |

1 set |

| Steady rest ( W.30 ) |

1 set |

1 set |

1 set |

(width : 15 mm ) |

| Wheel balancing stand |

The crankshaft grinder Model MQ8260A×2000 is the latest product modified on the base of the Model MQ8260A

and intended not only for use in automobile , tractor , diesel engine works and their repair shops to grind the journals and crank pins crankshaft , but also for use in large engineering machinery and diesel engines for ships to grind crankshaft .

﹣Four different work speeds are obtainable by making use of a double – speed motor and the belts in work head

﹣Union chucks are used in the headstock and tailstock for an adjustable eccentricity up to 120 mm

﹣Friction coupling is used in the headstock transmission chain for ifs easy adjustment.

﹣Table longitudinal traverse is operated either by hand or by power

﹣Wheelhead rapid approach and withdrawal is effected by hydraulic means

﹣Rolling guideways are used on wheelhead , and made by high quality material , the wheel spindle being of 80 mm in diameter has good rigidity and strength .

﹣Plastic coated bed ways with less friction

﹣The bed ways and wheelhead ways are lubricated in automatic cycle by means of oil pump.

﹣Additional synchronic for headstock and tailstock , i.e. the gears of headstock drive the tailstock to run in synchronism through the connecting spindle , thus . four different speed are obtainable . The length of works is ranged from 800 mm to 2000 mm.

﹣The digital display device can be optional.